Inhouse POLYSTOPP® QUICK CONNECT Demonstration

11th March 2020

The past years TDW has been doing a lot of R&D on the POLYSTOPP® equipment and they found a solution to make interventions both quicker and safer. The devolopped solution is called the POLYSTOPP® QUICK CONNECT. Before bringing new equipment in the market a series of tests have to be executed. In the final fase of testing, a field test with customer supervision has to be performed. An alternative for this would be to do simulated inhouse field test with supervision of customers.

As TDW contacted us to simulate a DN90 POLYSTOPP® intervention in supervision of some of our customers, we were happy to agree on this and to invite some end customers.

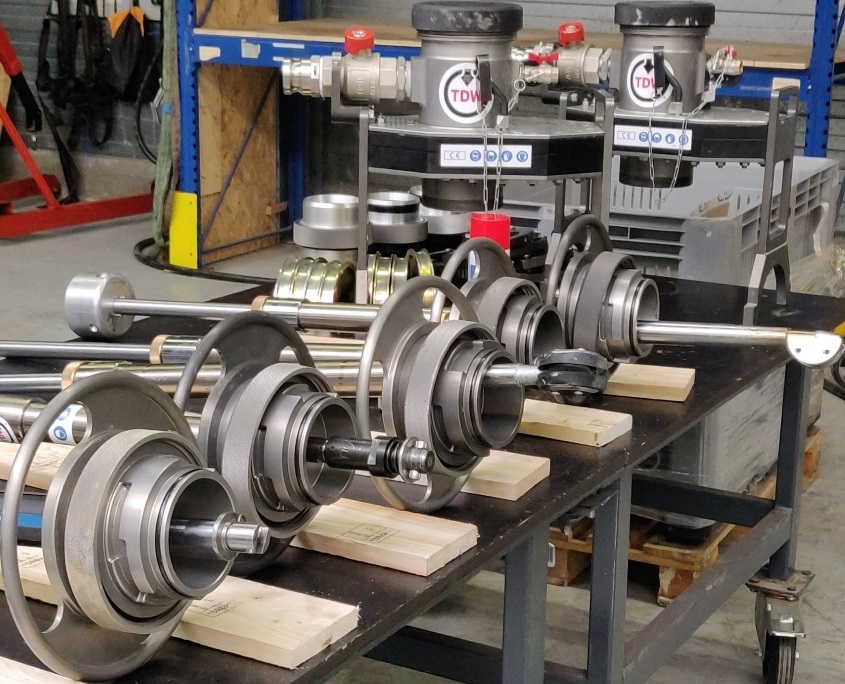

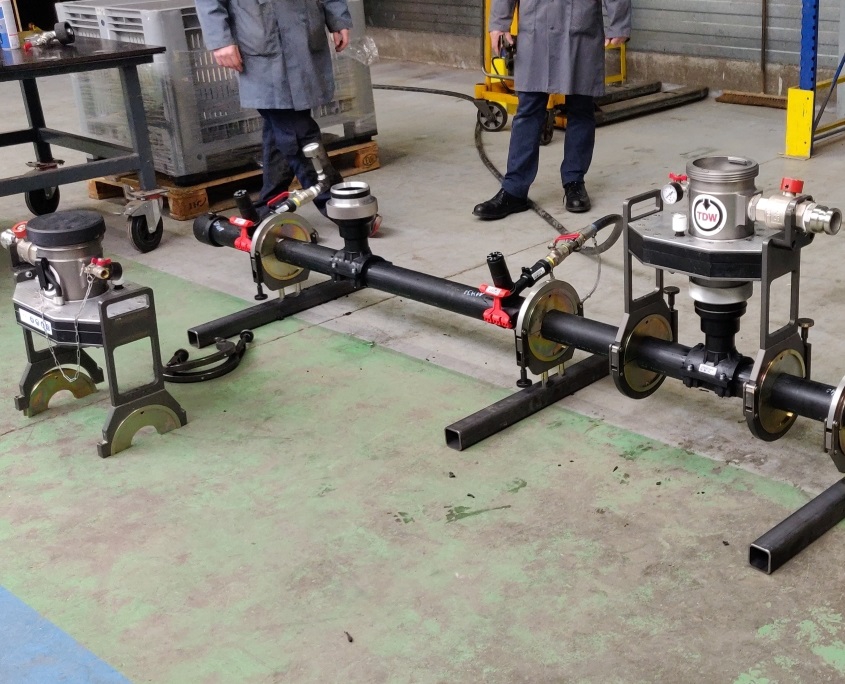

In the morning we presented a TDW presentation in which the new POLYSTOPP® QUICK CONNECT’s features, advantages and other properties were explained. The presentation was followed by the inhouse field test. TDW provided beside the new POLYSTOPP® equipment also a test rig on which the POLYSTOPP® fittings could first be welded, followed by a double position line stop operation with bypass. Before the line plugging heads could be inserted in the pipe, we needed to use the PS2000 tapping machine to drill trough the PE pipe.

When the simulated remedial work was performed, the plugging heads could be retracted and the completion plugs could be set.

The build-up of equipment and necessary intervention actions were executed by the attending customers with assistance of our OPS operators and with the supervision of a TDW POLYSTOPP engineer.

We want to thank our customers for attending the event and we want to thank TDW for assiting us in this event with all the equipment and one of their POLYSTOPP® QUICK CONNECT engineers.