Case study: Single Position ProStopp™ Intervention

17th january 2022

- Case:

In the Belgian province of Antwerp, we had some difficulties to carry out a classical Shortstopp® 275 intervention on a 12″ pipeline. The cause of this difficult intervention was a large ovality present on the 12″ pipeline. Thanks to the experience and expertise of our OPS operators, we were nevertheless successful in this job. A few weeks later, we were asked to perform another intervention on the same pipeline.

- Solution

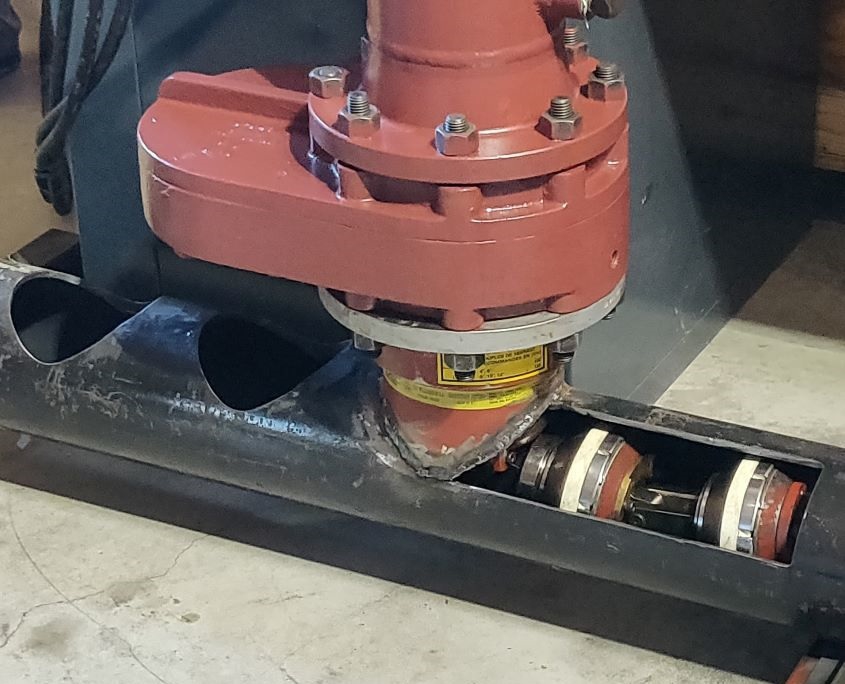

Recently, OPS invested in a 12″ ProStopp™ equipment which is universally applicable on 12″ pipes and insensitive to ovality. In the new intervention request we saw a perfect application for our new hydraulically activated double block and bleed equipment. (ProStopp™)

- Job execution

After the Hot-Tap was performed, it was time for the « moment supreme ». The ProStopp™ machine was placed on the pipe and after the « chip sweep » action, the ProStopp was installed and activated onto the pipe. After activating the Plugging Heads, the hydraulic pressure did not drop and we could test whether we had achieved a good sealing in the oval pipe.

Through the internal bleed port, we could check the sealing on both plugging heads.

The result was perfect! 100% seal on both primary and secondary plugging head.

The pipe was drained and after 2 OPS cold cuts, the customer carried out the necessary welding. After welding, the hydraulic pressure was released and the ProStopp™ was removed without any issues. All that followed was a successful completion to finish the job.